Landscape view is supported on PCs and tablets

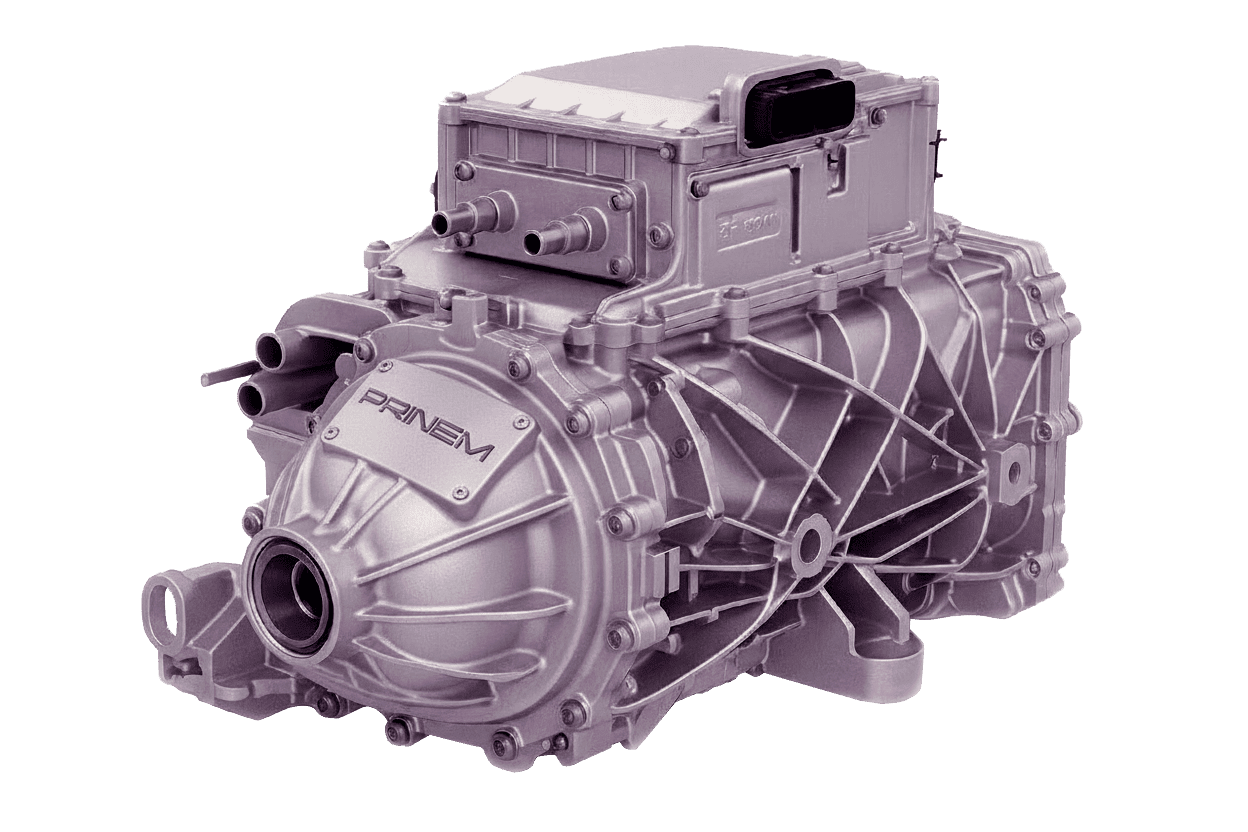

PRINEM iGear

PRINEM Induction (asynchronous) electric motor an innovative electric motor from PRINEM featuring a unique stator and rotor design, combined with electronic control for multi-mode operation. It acts as a built-in electromagnetic gearbox delivering a 12x effective RPM range and a more than 5x power increase (reducing the need for mechanical gearboxes by up to 80%)

Асинхронный электродвигатель PRINEM с инновационной конструкцией статора, ротора и электронным управлением с многорежимной работой, действующей

как «встроенная электромагнитная коробка передач» с 12-кратным диапазоном эффективных оборотов и более чем 5-кратным увеличением мощности (80% механических редукторов и КПП больше не требуются)

как «встроенная электромагнитная коробка передач» с 12-кратным диапазоном эффективных оборотов и более чем 5-кратным увеличением мощности (80% механических редукторов и КПП больше не требуются)

Асинхронный электродвигатель PRINEM с инновационной конструкцией статора, ротора и электронным управлением с многорежимной работой, действующей как «встроенная электромагнитная коробка передач» с 12-кратным диапазоном эффективных оборотов и более чем 5-кратным увеличением мощности (80% механических редукторов

и КПП больше не требуются)

и КПП больше не требуются)

Three Motor Modes

Achieved and validated performance

can be compared to a gearbox: when you shift into a higher "gear" (engaging Mode 2 or 3), power doubles and maximum torque

is reinstated

is reinstated

PRINEM iGear Asynchronous Motor fundamentally reshapes expectations for electric motors. Its key advantage—multi-mode

operation acting as a built-in electromagnetic gearbox with a 5x power increase—represents a true paradigm shift

operation acting as a built-in electromagnetic gearbox with a 5x power increase—represents a true paradigm shift

Without Increasing the Voltage

Energy Efficiency Improves as Power Grows

Wider effective RPM range: 1,000 rpm – 12,000 rpm

Power increase: 1 kW – 5.5 kW

5x

12x

01

12x effective RPM range without mechanical gear shifts

5x power increase without a voltage increase thanks to its three-mode configuration

5x power increase without a voltage increase

thanks to its three-mode configuration

thanks to its three-mode configuration

Maximum torque is available in each operational mode

Reduces the need for mechanical gearboxes and transmissions by 80%

– the entire functionality is achieved through electromagnetic interactions

within a compact motor

– the entire functionality is achieved through electromagnetic interactions

within a compact motor

Reduces the need for mechanical gearboxes

and transmissions by 80% – the entire functionality is achieved through electromagnetic interactions within a compact motor

and transmissions by 80% – the entire functionality is achieved through electromagnetic interactions within a compact motor

Energy savings – high efficiency without extreme currents or voltages

Key advantages

A conventional electric motor reaches peak power at its rated RPM after which torque drops. PRINEM overcomes this limitation with three operating modes

1. Mode 1 – Standard Cycle: Power and torque increase followed by a torque drop-off at high RPM (typical motor behavior)

2. Mode 2 – Power Boost: The motor increases power by 2.5x while maintaining the maximum torque level achieved in Mode 1

3. Mode 3 – Hyper Performance: The motor delivers up to 5x power with further RPM increase while sustaining maximum torque

Breakthrough in Electromechanics

Implementation of PRINEM technology enables upgrade up to 2+ MW for motors like Xiaomi Super Motor V8s (425 kW at 30,000 rpm).

However the most valuable and promising application is the ability

to shift the effective operating range to lower RPMs

However the most valuable and promising application is the ability

to shift the effective operating range to lower RPMs

Implementation of PRINEM technology enables upgrade up to 2+ MW for motors like Xiaomi Super Motor V8s (425 kW at 30,000 rpm). However the most valuable and promising application is the ability to shift the effective operating range to lower RPMs

Why This is a Game-Changer

Priority Sectors: Transport: Electric vehicles, railway, marine, aerospace

Priority Sectors:

Transport: Electric vehicles, railway, marine, aerospace

Transport: Electric vehicles, railway, marine, aerospace

Industrial: Pumps, compressors, heavy machinery

Application

1. Gain power and efficiency not by increasing RPM and voltage—a dead-end approach—but by achieving high efficiency and power at lower

RPM. For example, obtaining 1 MW of power within an effective RPM range of 2,500–30,000. Or 500–650 kW within a 2,000–20,000 RPM

range

RPM. For example, obtaining 1 MW of power within an effective RPM range of 2,500–30,000. Or 500–650 kW within a 2,000–20,000 RPM

range

1.Gain power and efficiency not by increasing RPM and voltage—a dead-end approach—but by achieving high efficiency and power at lower RPM. For example, obtaining 1 MW of power within an effective RPM range of 2,500–30,000. Or 500–650 kW within a 2,000–20,000 RPM range

2.Reduced battery power demand – peak power

is available without extreme current draws

is available without extreme current draws

End of the RPM and voltage race – PRINEM technology offers a smarter way

What This Means

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

PRINEM iGear

Асинхронный электродвигатель PRINEM с инновационной

конструкцией статора, ротора и электронным управлением с многорежимной работой, действующей как «встроенная электромагнитная коробка передач»

с 12-кратным диапазоном эффективных оборотов и более чем 5-кратным увеличением мощности (80% механических редукторов и КПП больше не требуются)

конструкцией статора, ротора и электронным управлением с многорежимной работой, действующей как «встроенная электромагнитная коробка передач»

с 12-кратным диапазоном эффективных оборотов и более чем 5-кратным увеличением мощности (80% механических редукторов и КПП больше не требуются)

PRINEM Induction (Asynchronous) Electric Motor

An innovative electric motor from PRINEM featuring

a unique stator and rotor design, combined with electronic control for multi-mode operation. It acts as a built-in electromagnetic gearbox delivering a 12x effective RPM range and a more than 5x power increase (reducing the need for mechanical gearboxes by up to 80%)

An innovative electric motor from PRINEM featuring

a unique stator and rotor design, combined with electronic control for multi-mode operation. It acts as a built-in electromagnetic gearbox delivering a 12x effective RPM range and a more than 5x power increase (reducing the need for mechanical gearboxes by up to 80%)

1

Асинхронный электродвигатель PRINEM iGear переворачивает представление о возможностях электромоторов. Его ключевое преимущество

– многорежимная работа, действующая как встроенная электромагнитная коробка передач при пятикратном росте мощности

– многорежимная работа, действующая как встроенная электромагнитная коробка передач при пятикратном росте мощности

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

Three Motor Modes

Achieved and Validated Performance

can be compared to a gearbox: when you shift into a higher "gear" engaging Mode 2 or 3), power doubles and maximum torque is reinstated

Efficiency Gains without a Voltage Increase

Energy Efficiency Improves as Power Grows

power increase: 1 kW – 5.5 kW

5x

wider effective RPM range: 1,000 rpm – 12,000 rpm

12x

2

3

12x effective RPM range without mechanical gear shifts

5x power increase without a voltage increase thanks to its three-mode configuration

Maximum torque is available in each operational mode

Reduces the need for mechanical gearboxes

and transmissions by 80% – the entire functionality

is achieved through electromagnetic interactions

within a compact motor

and transmissions by 80% – the entire functionality

is achieved through electromagnetic interactions

within a compact motor

Energy savings – high efficiency without extreme

currents or voltages

currents or voltages

Key Advantages

4

Mode 1 – Standard Cycle: Power and torque

increase followed by a torque drop-off at high

RPM (typical motor behavior)

increase followed by a torque drop-off at high

RPM (typical motor behavior)

Mode 2 – Power Boost: The motor increases

power by 2.5x while maintaining the maximum

torque level achieved in Mode 1

power by 2.5x while maintaining the maximum

torque level achieved in Mode 1

Mode 3 – Hyper Performance: The motor delivers

up to 5x power with further RPM increase while

sustaining maximum torque

up to 5x power with further RPM increase while

sustaining maximum torque

Breakthrough in Electromechanics

A conventional electric motor reaches peak

power at its rated RPM after which torque drops.

PRINEM overcomes this limitation with three

operating modes

power at its rated RPM after which torque drops.

PRINEM overcomes this limitation with three

operating modes

5

Implementation of PRINEM technology enables

upgrade up to 2+ MW for motors like Xiaomi Super Motor V8s (425 kW at 30,000 rpm). However the most valuable and promising application is the ability to shift the effective operating range to lower RPMs

upgrade up to 2+ MW for motors like Xiaomi Super Motor V8s (425 kW at 30,000 rpm). However the most valuable and promising application is the ability to shift the effective operating range to lower RPMs

Why This is a Game-Changer ?

Priority Sectors: Transport: electric vehicles, railway, marine, aerospace.

Industrial: pumps, compressors, heavy machinery

Industrial: pumps, compressors, heavy machinery

Note: PRINEM iGear enables a locomotive to accelerate to 1200 km/h (with a full load despite

aerodynamic resistance)

aerodynamic resistance)

Applications

6

1.Gain power and efficiency not by increasing RPM and voltage—a dead-end approach—but by +achieving high efficiency and power at lower RPM. For example, obtaining 1 MW of power within an effective RPM range of 2,500–30,000. Or 500–650 kW within a 2,000–20,000 RPM range

2.Reduced battery power demand – peak power

is available without extreme current draws

is available without extreme current draws

3.End of the RPM and voltage race –

PRINEM technology offers a smarter way

PRINEM technology offers a smarter way

What This Means ?

PRINEM iGear Asynchronous Motor

fundamentally reshapes expectations

for electric motors. Its key advantage—multi-mode operation acting as a built-in electromagnetic gearbox with a 5x power increase—represents a true paradigm shift

fundamentally reshapes expectations

for electric motors. Its key advantage—multi-mode operation acting as a built-in electromagnetic gearbox with a 5x power increase—represents a true paradigm shift

7

PRINEM Adaptive EM-9.3.3

A 9-phase induction motor with a winding commutation system featuring a triple nominal power range and 3x fault tolerance

Breakthrough in electrical engineering for the first time in history it is possible

to integrate any number of fully isolated windings. this can consist of multiple

three-phase winding sets or polyphase systems where each slot winding acts

as an independent phase

to integrate any number of fully isolated windings. this can consist of multiple

three-phase winding sets or polyphase systems where each slot winding acts

as an independent phase

Up to 50%

increase in overload capacity

Up to 50%

reduction in energy consumption

2-3x

extended service life

Enhanced Reliability

System remains operational even if part of the windings fail

Up to 50%

lower operating temperature

IE4+ Efficiency Class

exceeds global standards

02

02

Key Advantages

3 sets of fully isolated three-phase windings ensure enhanced fault tolerance and high power density

Active winding commutation maintains peak efficiency across the entire power range and optimizes energy consumption based on load

The 9-phase architecture significantly eliminates the risk of failure

Provides maximum performance over the entire operating range

Intelligent phase control maintains optimal consumption and maximum efficiency under variable load

Technical Superiority

Ideal for industries requiring any induction or synchronous motors that operate under variable load, delivering maximum energy savings and high fault tolerance

Applications

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

Breakthrough in electrical engineering hor the first time

in history it is possible to integrate any number of fully isolated windings. This can consist of multiple three-phase winding sets or polyphase systems where each slot

winding acts as an independent phase

in history it is possible to integrate any number of fully isolated windings. This can consist of multiple three-phase winding sets or polyphase systems where each slot

winding acts as an independent phase

PRINEM Adaptive EM-9.3.3

A 9-phase induction motor with a winding commutation system featuring a triple nominal power range and 3x fault tolerance

1

reduction in energy consumption

2-3x

extended service life

Enhanced Reliability

system remains operational even if part of the windings fail

Up to 50%

lower operating temperature

IE4+ Efficiency Class:

exceeds global standards

Up to 50%

increase in overload capacity

Up to 50%

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

2

Key Advantages

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

3 sets of fully isolated three-phase windings ensure enhanced fault tolerance and high power density

Active winding commutation maintains peak efficiency across the entire power range and optimizes energy consumption based on load

Key Advantages

3

The 9-phase architecture significantly reduces the risk of failure

Provides maximum performance throughout the entire operating range

Intelligent phase control maintains optimal consumption and maximum efficiency under variable load

Technical Superiority

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

4

Ideal for industries requiring any induction or synchronous motors that operate under variable load, delivering maximum energy savings and high fault tolerance

Applications

PRINEM IronForce SR

simple and low-cost control system

Controller

Universal switched reluctance electric motor (SRM) with applications ranging from scooters to heavy-duty trucks and locomotives

A cheap, simple, reliable, durable, and highly efficient synchronous motor with an adaptive form factor—available

in a standard housing or as the world's first PRINEM in-wheel motor, through a complete understanding of its underlying physics. This marks only the fourth fundamental in-wheel motor design in the history of electric propulsion

in a standard housing or as the world's first PRINEM in-wheel motor, through a complete understanding of its underlying physics. This marks only the fourth fundamental in-wheel motor design in the history of electric propulsion

Ultimate Design Simplicity

30-40%

lower production cost compared to PMSM (synchronous electric motor)

Excellent Freewheeling

high free-rolling efficiency with no resistance when unpowered

Rotor is Made Entirely of Steel

design uses no magnets or windings

Unmatched Reliability and Durability

03

03

A dream solution for both manufacturers and end-users of electric transport from scooters and bicycles to EVs, heavy

trucks and locomotives

trucks and locomotives

An electric motor with a broad application spectrum. Ideal for any application demanding high efficiency, simplicity and extreme durability especially in harsh operating conditions

1.Transport (from scooters to heavy trucks and locomotives)

3.Other specialized electric motor applications

2.Industrial equipment

Applications

This electric motor is available in various designs, from a cylindrical

form to a fully integrated wheel motor

Compact: Matches the compact size of permanent magnet motors

(the industry benchmark for power density)

The World First: PRINEM introduces the world's first switched reluctance wheel motor

form to a fully integrated wheel motor

Compact: Matches the compact size of permanent magnet motors

(the industry benchmark for power density)

The World First: PRINEM introduces the world's first switched reluctance wheel motor

Key advantages

Versatile Form Factor

Versatile Form Factor

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

PRINEM IronForce SR

Universal switched reluctance electric motor (SRM) with applications ranging from scooters to heavy-duty trucks and locomotives

A cheap, simple, reliable, durable, and highly efficient synchronous motor with an adaptive form factor—available in a standard housing or as the world's first PRINEM in-wheel motor, through a complete understanding of its underlying physics. This marks only the fourth fundamental in-wheel motor design in the history of electric propulsion

1

design uses no magnets or windings

Unmatched Reliability and Durability

Ultimate Design Simplicity

Excellent Freewheeling

high free-rolling efficiency with no resistance

when unpowered

when unpowered

30-40%

lower production cost compared to PMSM (synchronous electric motor)

Rotor is Made Entirely of Steel

simple and low-cost control system

Controller

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

2

Key Advantages

Высочайшая надежность и живучесть

Высокая эффективность свободного хода

Высокий накат без подачи питания на двигатель

Контроллер

A dream solution for both manufacturers

and end-users of electric transport from scooters and bicycles to EVs, heavy trucks and locomotives

and end-users of electric transport from scooters and bicycles to EVs, heavy trucks and locomotives

An electric motor with a broad application

spectrum. Ideal for any application demanding

high efficiency, simplicity and extreme durability

especially in harsh operating conditions

spectrum. Ideal for any application demanding

high efficiency, simplicity and extreme durability

especially in harsh operating conditions

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

3

1.Transport (from scooters to heavy trucks and locomotives)

3.Other specialized electric motor applications

2.Industrial Equipment

Applications

Высочайшая надежность и живучесть

Высокая эффективность свободного хода

Высокий накат без подачи питания на двигатель

Простая и дешевая система управления

Контроллер

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

4

This electric motor is available in various designs,

from a cylindrical form to a fully integrated wheel

motor

from a cylindrical form to a fully integrated wheel

motor

Compact: Matches the compact size of permanent magnet motors (the industry benchmark for power density)

The world first: PRINEM introduces the world's

first switched reluctance wheel motor

first switched reluctance wheel motor

Key Advantages

Versatile Form Factor

Versatile Form Factor

PRINEM IE5 Ultimate

5x

extended service life

The world's first and only direct-on-line induction motor to achieve

the IE5 efficiency class and reach the physical design limit

of efficiency without a variable frequency drive setting

the benchmark for performance

Capable of replacing multiple motors in a system and withstanding

an overload with a service factor of 3.0-4.0 (S2 duty cycle)

the IE5 efficiency class and reach the physical design limit

of efficiency without a variable frequency drive setting

the benchmark for performance

Capable of replacing multiple motors in a system and withstanding

an overload with a service factor of 3.0-4.0 (S2 duty cycle)

Breaking the paradigm according to the international standard IEC

60034-30-2, the 5th class of energy efficiency for electric motors

and generators (IE5) can only be achieved when they are controlled

by a frequency converter

PRINEM IE5 Ultimate electric motor shatters this existing paradigm

by operating directly from the mains power supply while providing reduced energy consumption

60034-30-2, the 5th class of energy efficiency for electric motors

and generators (IE5) can only be achieved when they are controlled

by a frequency converter

PRINEM IE5 Ultimate electric motor shatters this existing paradigm

by operating directly from the mains power supply while providing reduced energy consumption

Minimal Acoustic Noise

20-40%

reduced energy consumption

Exceptional Overload Capacity - Over 300%

higher (Peak Torque) compared to IE3 motors

30-40°C

lower winding temperature

Extremely Wide Power Range Compared to Conventional Induction Motors

04

04

Uses standard industrial materials

Produced on standard industrial equipment

Requires no overhaul of conventional induction motor manufacturing processes

Produced on standard industrial equipment

Requires no overhaul of conventional induction motor manufacturing processes

Key Advantages

The cost of a VFD (controller) can exceed that of the motor itself. PRINEM's solution eliminates this expense by redefining standards—it operates directly from the power grid requiring no frequency

converter or electronic control system

converter or electronic control system

No Variable Frequency Drive (VFD) Required

This electric motor can be used anywhere where increased size

is not a critical constraint, but reduced energy consumption

and operation under variable load (with a 4x power reserve) are required. This operational advantage compensates for its higher initial cost during its service life. (It offers a multiple safety margin

for torque during power overloads)

is not a critical constraint, but reduced energy consumption

and operation under variable load (with a 4x power reserve) are required. This operational advantage compensates for its higher initial cost during its service life. (It offers a multiple safety margin

for torque during power overloads)

Applications

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

PRINEM IE5 Ultimate

The world's first and only direct-on-line induction motor

to achieve the IE5 efficiency class and reach the physical design limit of efficiency without a variable frequency drive setting the benchmark for performance

Capable of replacing multiple motors in a system and withstanding an overload with a service factor of 3.0-4.0 (S2 duty cycle)

to achieve the IE5 efficiency class and reach the physical design limit of efficiency without a variable frequency drive setting the benchmark for performance

Capable of replacing multiple motors in a system and withstanding an overload with a service factor of 3.0-4.0 (S2 duty cycle)

1

20-40%

reduced energy consumption

5x

extended service life

30-40°C

lower winding temperature

Exceptional Overload Capacity - Over 300%

higher (peak torque) compared to IE3 motors

Extremely Wide Power Range Compared to Conventional Induction Motors

Minimal Acoustic Noise

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

2

Key advantages

Uses standard industrial materials

Breaking the paradigm according to the international standard IEC 60034-30-2, the 5th class of energy efficiency for electric motors and generators (IE5) can only be achieved when they are controlled by a frequency converter

PRINEM IE5 Ultimate electric motor shatters this

existing paradigm by operating directly from the mains power supply while providing reduced energy consumption

PRINEM IE5 Ultimate electric motor shatters this

existing paradigm by operating directly from the mains power supply while providing reduced energy consumption

Produced on standard industrial equipment

Requires no overhaul of conventional induction

motor manufacturing processes

motor manufacturing processes

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

3

Key Advantages

The cost of a VFD (controller) can exceed that of the motor itself. PRINEM's solution eliminates this expense by redefining standards—it operates directly from the power grid requiring no frequency converter or electronic control system

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

4

No Variable Frequency Drive (VFD) Required

This electric motor can be used anywhere where

increased size is not a critical constraint, but reduced energy consumption and operation under variable load (with a 4x power reserve) are required. This operational advantage compensates for its higher initial cost during its service life. (It offers a multiple safety margin for torque during power overloads)

increased size is not a critical constraint, but reduced energy consumption and operation under variable load (with a 4x power reserve) are required. This operational advantage compensates for its higher initial cost during its service life. (It offers a multiple safety margin for torque during power overloads)

Applications

05

PRINEM RoboStep

Unmatched Holding Force when Uncommutated

Voltage is Applied

Voltage is Applied

Synchronous symmetrical design torque ripple-free electric motor engineered to deliver outstanding starting torque, exceptional overload capacity, powerful holding force and stepper mode

In classical motor engineering theory RoboStep motor should not be able to operate at all. This motor has an equal number of rotor and stator elements whose interaction is similar to the

function of a circular electromagnet

Imagine a design incorporating 50 electromagnets. Such

a motor possesses unprecedented traction, starting torque from standstill and rotational acceleration dynamics

function of a circular electromagnet

Imagine a design incorporating 50 electromagnets. Such

a motor possesses unprecedented traction, starting torque from standstill and rotational acceleration dynamics

Unprecedented Starting Torque Right rom Standstill

Record-Breaking Overload Capacity

Stepper Mode

the precision of a stepper motor combined with

the power of a synchronous electric motor

the power of a synchronous electric motor

Record-Breaking Acceleration Dynamics

Up to 50%

lower operating temperature compared to conventional analogues that allows use of inexpensive magnets without the risk of demagnetization

motor reaches operating speed (RPM) in a "burst" with triple shaft overload when power is applied within the time it takes to pass from one magnet to the next

05

A simple cost-effective PRINEM-designed controller

Motor service life is multiple times higher than that of conventional analogues

The Problem with Conventional Steppers: They are inherently inefficient and their performance degrades as power increases. The PRINEM Solution: Our motor maintains high efficiency and all key performance characteristics in stepper mode even at elevated power levels

Key Advantages

Robotics, robotic arms, lifting mechanisms, conveyor belts, traction

motors for heavy-duty vehicles, drilling rigs, presses, and any technical

segment requiring immense overload capacity, the precise characteristics

of a high-power stepper motor with strong holding force, and maximum

torque from a standstill point.

motors for heavy-duty vehicles, drilling rigs, presses, and any technical

segment requiring immense overload capacity, the precise characteristics

of a high-power stepper motor with strong holding force, and maximum

torque from a standstill point.

Applications

The motor is manufactured similarly to the simplest permanent

magnet synchronous motor—making it multiple times cheaper

than a conventional stepper motor while outperforming it in every metric

magnet synchronous motor—making it multiple times cheaper

than a conventional stepper motor while outperforming it in every metric

Efficiency + Value

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

PRINEM RoboStep

Synchronous symmetrical design torque ripple-free

electric motor engineered to deliver outstanding starting torque, exceptional overload capacity, powerful holding force and stepper mode.

High-efficiency industrial solution is capable of substantially reducing costs in robotics while significantly boosting its overall effectiveness

electric motor engineered to deliver outstanding starting torque, exceptional overload capacity, powerful holding force and stepper mode.

High-efficiency industrial solution is capable of substantially reducing costs in robotics while significantly boosting its overall effectiveness

1

Record-Breaking Overload Capacity

Unmatched Holding Force

when uncommutated voltage is applied

Stepper Mode

the precision of a stepper motor combined with the power of a synchronous electric motor

Record-Breaking Acceleration Dynamics

the motor reaches operating speed (RPM) in a "burst" with triple shaft overload when power is applied within the time it takes to pass from one magnet to the next

Up to 50%

lower operating temperature compared to conventional analogues that allows use of inexpensive magnets without the risk of demagnetization

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

2

Key Advantages

A simple cost-effective PRINEM-designed controller

Motor service life is multiple times higher than that

of conventional analogues

of conventional analogues

The problem with conventional steppers: they are inherently inefficient and their performance degrades as power increases.

The PRINEM solution: our motor maintains high

efficiency and all key performance characteristics in stepper mode even at elevated power levels

The PRINEM solution: our motor maintains high

efficiency and all key performance characteristics in stepper mode even at elevated power levels

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

3

Key advantages

In classical motor engineering theory RoboStep motor should not be able to operate at all. This motor has an equal number of rotor and stator elements whose interaction is similar to the function of a circular electromagnet

Imagine a design incorporating 50 electromagnets. Such a motor possesses unprecedented traction, starting torque from standstill and rotational acceleration dynamics

Imagine a design incorporating 50 electromagnets. Such a motor possesses unprecedented traction, starting torque from standstill and rotational acceleration dynamics

Unprecedented starting torque right from standstill

The motor is manufactured similarly to the simplest permanent magnet synchronous motor—making it multiple times cheaper than a conventional stepper motor while outperforming it in every metric

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

4

Efficiency + Value

Robotics, robotic arms, lifting mechanisms, conveyor belts, traction motors for heavy-duty vehicles, drilling rigs, presses, and any technical segment requiring immense overload capacity, the precise characteristics of a high-power stepper motor with strong holding force, and maximum torque from a standstill point

Applications

PRINEM Maxinus EM

The world's most efficient synchronous electric motor by PRINEM featuring a non-salient pole permanent magnet rotor. It achieves sinusoidal electromagnetic interaction between the rotor and stator—a practical implementation of the Halbach array

A permanent magnet motor delivering significantly higher performance and the highest physically achievable synchronous rotor efficiency

Reduced Acoustic Noise

20–50%

wider power range compared to standard synchronous motors

Up to 70%

higher overload capacity (maximum torque)

Peak Efficiency at the Physical Limit

2-3x

extended service life

Up to 30%

lower production cost

30-50%

lower operating temperature

06

06

The world's only permanent magnet motor with a smooth transition between poles, ensuring maximum sinusoidal rotor-stator field interaction and optimal energy conversion efficiency

Key Advantages

Any deviation from it reduces rotor-stator field interaction which is why a non-salient pole rotor delivers superior efficiency

The Sine Wave is the Most Efficient Waveform

The rotor is a drop-in replacement for standard induction motor stators while maintaining full compatibility with original (conventional) drive

systems (controller)

systems (controller)

Direct Integration

EV, locomotives, ships, heavy-duty trucks, etc.

Any application requiring the highest energy efficiency in synchronous motors.

This motor is suitable wherever significant increases in power, maximum torque (overload capacity), and a substantial extension of the operating (effective) RPM range are required

Any application requiring the highest energy efficiency in synchronous motors.

This motor is suitable wherever significant increases in power, maximum torque (overload capacity), and a substantial extension of the operating (effective) RPM range are required

Applications

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

PRINEM Maxinus EM

The world's most efficient synchronous electric motor by PRINEM featuring a non-salient pole permanent magnet rotor. It achieves sinusoidal electromagnetic interaction between the rotor and stator—a practical implementation of the Halbach array

A permanent magnet motor delivering significantly higher performance and the highest physically achievable synchronous rotor efficiency

1

20–50%

wider power range compared to standard synchronous motors

Up to 30%

lower production cost

30-50%

lower operating temperature

Up to 30-50%

Reduced Acoustic Noise

Высочайшая эффективность на физических пределах

lower operating temperature

Up to 70%

higher overload capacity (maximum torque)

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

2

Key Advantages

Peak Efficiency at the Physical Limit

The World's Only Permanent Magnet Motor

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

with a smooth transition between poles, ensuring maximum sinusoidal rotor-stator field interaction and optimal energy conversion efficiency

The Sine Wave is the Most Efficient Waveform

any deviation from it reduces rotor-stator field

interaction which is why a non-salient pole rotor

delivers superior efficiency

interaction which is why a non-salient pole rotor

delivers superior efficiency

Direct lntegration

the rotor is a drop-in replacement for standard

induction motor stators while maintaining

full compatibility with original (conventional) drive

systems (controller)

induction motor stators while maintaining

full compatibility with original (conventional) drive

systems (controller)

3

Key Advantages

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

4

EV, locomotives, ships, heavy-duty trucks, etc.

Any application requiring the highest energy

efficiency in synchronous motors

This motor is suitable wherever significant increases in power, maximum torque (overload capacity), and a substantial extension of the operating (effective) RPM range are required

Any application requiring the highest energy

efficiency in synchronous motors

This motor is suitable wherever significant increases in power, maximum torque (overload capacity), and a substantial extension of the operating (effective) RPM range are required

Applications

PRINEM Alu-Tech

Aluminum Winding Technology - replacing copper with aluminum in stator windings while simultaneously improving energy efficiency and achieving record-low operating temperatures

Enables direct replacement of copper windings with aluminum windings

in motors and generators while maintaining* original frame (dimensions),

offering manufacturers a global solution for transitioning from copper

to aluminum windings

*In low-power motors an increase of one frame size may be required

in motors and generators while maintaining* original frame (dimensions),

offering manufacturers a global solution for transitioning from copper

to aluminum windings

*In low-power motors an increase of one frame size may be required

Improved Energy Efficiency Class

IE3-IE4+

IE3-IE4+

Extended Maintenance Intervals

Future Price Stability and Resilient Aluminum

Supply Chain

Supply Chain

2-3x

6x

reduction in winding cost

extended service life

Reduced Weight

of Motor/Generator

of Motor/Generator

50-70%

lower winding temperature

07

07

Suitable for both motors and generators of synchronous

and asynchronous types

and asynchronous types

Universal Solution

Global aluminum reserves exceed copper reserves by million time.

Copper prices will rise non-linearly compared to aluminum prices

making PRINEM Alu-Tech a forward-looking choice for the fast-growing electric motor market.

making PRINEM Alu-Tech a forward-looking choice for the fast-growing electric motor market.

Strategic Economic Advantage

All induction and synchronous motors and generators with following priorities: cost reduction, durability and extended

maintenance intervals

maintenance intervals

Applications

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

PRINEM Alu-Tech

Aluminum Winding Technology - replacing copper with aluminum in stator windings while simultaneously improving energy efficiency and achieving record-low operating temperatures

Enables direct replacement of copper windings with aluminum windings in motors and generators while maintaining* original frame (dimensions), offering manufacturers a global solution for transitioning from copper to aluminum windings

1

50-70%

lower winding temperature

Improved Energy Efficiency Class

(IE3-IE4+)

(IE3-IE4+)

Reduced Weight of Motor/Generator

Extended Maintenance Intervals

Future Price Stability

resilient aluminum supply chain

2-3x

Высочайшая эффективность на физических пределах

extended service life

6x

reduction in winding cost

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

2

Key Advantages

3

Suitable for both motors and generators of synchronous and asynchronous types

Universal Solution

Global aluminum reserves exceed copper reserves by million time

Copper prices will rise non-linearly compared to aluminum prices making PRINEM Alu-Tech a forward-looking choice for the fast-growing electric motor market

Strategic Economic

Advantage

Advantage

All induction and synchronous motors and generators with following priorities: cost reduction, durability and extended maintenance intervals

Applications

PRINEM Smart

Synchronous or Asynchronous VFD electric motor with record-breaking reductions in size, weight and cost

The true value of PRINEM SMART motors isn't

just in their lower price but in their new

technological capabilities they make possible

just in their lower price but in their new

technological capabilities they make possible

Reduced Noise Levels

200–300%

wider power range

Up to 40%

higher overload capacity (peak torque )

Higher Efficiency

2-3x

smaller/Lighter for equivalent power

50%

lower production cost

30%

lower operating temperature

08

Improved IE Energy Efficiency Class Compared to

a Standard Larger Model

a Standard Larger Model

08

PRINEM SMART technology enables a revolutionary reduction

in motor size and weight, while simultaneously achieving

in motor size and weight, while simultaneously achieving

1. Higher power output

2. No increase in RPM

3. No increase in voltage

4. Improved efficiency

5. Enhanced overload capacity

Key Advantages

Traction (transport) motors, industrial motors, special-purpose motors, submersible motors, etc.

Applications

For instance, submersible motors by PRINEM SMART technology enables the equipment that is twice as light and twice

as compact for oil extraction (equipment that is 50%

lighter and 50% smaller).

as compact for oil extraction (equipment that is 50%

lighter and 50% smaller).

Standard Submersible Pump

PRINEM Submersible Pump

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

PRINEM Smart

Synchronous or Asynchronous VFD electric motor

with record-breaking reductions in size, weight and

cost

with record-breaking reductions in size, weight and

cost

The true value of PRINEM SMART motors isn't just

in their lower price but in their new technological capabilities they make possible

in their lower price but in their new technological capabilities they make possible

1

200–300%

wider power range

30%

Reduced Noise Levels

Higher Efficiency

lower operating temperature

50%

lower production cost

2-3x

smaller/lighter for equivalent power

Up to 40% higher

overload capacity (peak torque )

2

Key Advantages

Improved IE Energy Efficiency Class Compared to a Standard Larger Model

PRINEM SMART technology enables a revolutionary reduction in motor size and weight, while simultaneously achieving

1. Higher power output

2. No increase in RPM

3. No increase in voltage

4. Improved efficiency

5. Enhanced overload capacity

3

Key Advantages

Traction (transport) motors, industrial motors,

special-purpose motors, submersible motors, etc.

special-purpose motors, submersible motors, etc.

For instance, submersible motors by PRINEM SMART technology enables the equipment that is twice as light and twice as compact for oil extraction (equipment that is 50% lighter and 50% smaller)

4

Applications

Standard Submersible

Pump

Pump

PRINEM Submersible

Pump

Pump

PRINEM Axial

More Compact Cooling System

PRINEM Axial Flux permanent magnet synchronous motor

Axial flux motors represent the most advanced physical configuration

for magnetic and current circuits today. However they are complex

to manufacture, requiring specialized production equipment

and sophisticated costly controllers, coupled with a complex

and powerful cooling system

PRINEM technology dramatically improves motor reliability and energy efficiency while reducing the total system cost including controller and

cooling system cost.

for magnetic and current circuits today. However they are complex

to manufacture, requiring specialized production equipment

and sophisticated costly controllers, coupled with a complex

and powerful cooling system

PRINEM technology dramatically improves motor reliability and energy efficiency while reducing the total system cost including controller and

cooling system cost.

Reduced Inrush Currents

Up to 50 %

lower motor controll unit cost

30 to 100%

higher max. RPM & effective

frequency

frequency

2-3x

improvement in reliability and service life

20%+

Up to 50%

higher overload capacity / peak torque

lower operating temperature

Up to 30%

power increase

09

09

PRINEM axial flux electric motors deliver increased power and overload capacity while operating at lower temperatures. Technology reduces manufacturing cost of the associated controller

Key Advantages

EV Traction motors, aviation, and robotics. Any application requiring the highest possible power-to-weight ratio (kW per kg of motor

weight)

weight)

Applications

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

PRINEM Axial

PRINEM Axial flux permanent magnet

synchronous motor

synchronous motor

Axial flux motors represent the most advanced physical configuration for magnetic and current circuits today. However they are complex to manufacture, requiring specialized production equipment and sophisticated costly controllers, coupled with a complex and powerful cooling system

PRINEM technology dramatically improves motor reliability and energy efficiency while reducing the total system cost including controller and cooling system cost

PRINEM technology dramatically improves motor reliability and energy efficiency while reducing the total system cost including controller and cooling system cost

1

Up to 30%

power increase

50 %

Reduced Inrush Currents

lower motor controll unit cost

30 to 100%

higher max. RPM & effective frequency

2-3x

improvement in reliability and service life

More Compact Cooling System

20%+

higher overload capacity / peak torque

Up to 50%

lower operating temperature

2

Key Advantages:

3

PRINEM axial flux electric motors deliver increased power and overload capacity while operating at lower temperatures. Technology reduces manufacturing cost of the associated controller

Key Advantages

Any application requiring the highest possible

power-to-weight ratio (kW per kg of motor weight)

power-to-weight ratio (kW per kg of motor weight)

Applications

10

PRINEM e-Diff DualDrive

Weight Reduction

Compatibility

available as a nine-phase system and compatible with other PRINEM options

An innovative dual-rotor induction motor with an integrated controlled electromagnetic differential

A world-first innovation: the functions of a mechanical differential are achieved through electromagnetic interactions (no gears) and integrated directly into

the electric motor's design. This provides a unique combination of technical capabilities, resulting in a more compact, lighter, and more reliable system

the electric motor's design. This provides a unique combination of technical capabilities, resulting in a more compact, lighter, and more reliable system

Cost Reduction

Simple Design

High Efficiency

Extended Service Life

Electromagnetic Differential

Two Independent Rotors

10

The motor contains two independent rotors that can rotate at different speeds based on the load. These are designed to be connected directly to a vehicle's half-shafts with the differential function achieved electromagnetically rather than through mechanical parts

The world's first electric motor where the motor itself performs the function of a mechanical differential

How It Works ?

The controller's volt-per-hertz (V/f) characteristic manages the locking torque—determining whether the rotors (and thus the half-shafts) are forced to spin at the same speed (RPM) or are allowed to slip under differing loads—and manages torque distribution between them

Controlled Electromagnetic Differential

Eliminating the mechanical differential simplifies the drivetrain and reduces

its overall weight. The motor is designed as a simple, durable, lightweight

and efficient direct drive

its overall weight. The motor is designed as a simple, durable, lightweight

and efficient direct drive

Reduced Cost & Weight

Its simplicity, durability and high efficiency make it an optimal solution for city cars, affordable family EV and light/medium-duty trucks

Primary: automotive, agricultural machinery

Ideal for commercial transport

Applications

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

PRINEM e-Diff DualDrive

An innovative dual-rotor induction motor with

an integrated controlled electromagnetic differential

an integrated controlled electromagnetic differential

A world-first innovation: the functions of a mechanical differential are achieved through electromagnetic interactions (no gears) and integrated directly into

the electric motor's design. This provides a unique combination of technical capabilities, resulting in a more

compact, lighter, and more reliable system

the electric motor's design. This provides a unique combination of technical capabilities, resulting in a more

compact, lighter, and more reliable system

1

Compatibility

available as a nine-phase system and compatible

with other PRINEM options

with other PRINEM options

Cost Reduction

Weight Reduction

Two Independent Rotors

Electromagnetic Differential

Simple Design

Extended Service Life

High Efficiency

2

Key advantages

3

The motor contains two independent rotors that can rotate at different speeds based on the load. These are designed to be connected directly to a vehicle's half-shafts with the differential function achieved electromagnetically rather than through mechanical parts

The world's first electric motor where the motor itself performs the function of a mechanical differential

How It Works ?

The controller's volt-per-hertz (V/f) characteristic manages the locking torque—determining whether the rotors (and thus the half-shafts) are forced to spin at the same speed (RPM) or are allowed to slip under differing loads—and manages torque distribution between them

Controlled Electromagnetic Differential

4

Eliminating the mechanical differential simplifies the drivetrain and reduces its overall weight. The motor is designed as a simple, durable, lightweight and efficient direct drive

Reduced Cost & Weight

Its simplicity, durability and high efficiency make it an optimal solution for city cars, affordable family EV and light/medium-duty trucks

Primary: automotive,agricultural machinery

Ideal for commercial transport

Applications

11

PRINEM High-Voltage AC Synchronous Motors

An innovative solution that completely eliminates the traditional drawbacks of high-voltage motors while simultaneously reducing weight, energy consumption and increasing energy efficiency

PRINEM technology delivers breakthrough improvements in high-voltage motor performance, transforming them from archaic systems with inherent problems into a modern, technically sophisticated product

Increased Energy Efficiency (IE Class)

15–40%

reduction in size/weight

Easy Startup

reduces startup time and enhances operational

performance

performance

Higher Efficiency

minimizes unaccounted losses and reduces armature

excitation current

excitation current

Cost Reduction ≥30%

while maintaining original technical and operational specifications

11

Compatible with the PRINEM Alu-Tech aluminum winding system - a cost-effective material option

Compatibility

PRINEM high-voltage, high-efficiency AC motor with its simplified starting system is ideal for the following sectors: all types of pipeline systems high-power pumping stations high-capacity ventilation systems mining industry (from hoist drives to dewatering pumps) heavy machinery manufacturing walking excavators high-power conveyor systems, etc.

Application

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

PRINEM High-Voltage AC Synchronous Motors

An innovative solution that completely eliminates

the traditional drawbacks of high-voltage motors

while simultaneously reducing weight, energy

consumption and increasing energy efficiency

the traditional drawbacks of high-voltage motors

while simultaneously reducing weight, energy

consumption and increasing energy efficiency

PRINEM technology delivers breakthrough

improvements in high-voltage motor

performance, transforming them from archaic

systems with inherent problems into a modern,

technically sophisticated product

improvements in high-voltage motor

performance, transforming them from archaic

systems with inherent problems into a modern,

technically sophisticated product

1

Simplified Startup

reduces startup time and enhances operational

performance

performance

Cost Reduction ≥30%

while maintaining original technical and operational specifications

Higher Efficiency

minimizes unaccounted losses and reduces armature excitation current

15–40%

Increased Energy Efficiency (IE class)

reduction in size/weight

2

Key Advantages

3

Compatible with the PRINEM Alu-Tech aluminum

winding system - a cost-effective material option

winding system - a cost-effective material option

Compatibility

PRINEM high-voltage, high-efficiency AC motor with

its simplified starting system is ideal for the following sectors: All types of pipeline systems High-power pumping stations High-capacity ventilation systems mining industry (from hoist drives to dewatering pumps) heavy machinery manufacturing Walking excavators High-power conveyor systems, etc.

its simplified starting system is ideal for the following sectors: All types of pipeline systems High-power pumping stations High-capacity ventilation systems mining industry (from hoist drives to dewatering pumps) heavy machinery manufacturing Walking excavators High-power conveyor systems, etc.

Application

PRINEM PowerRing

Ideal for Integration Into Existing Systems

Innovative induction motor design for industrial solutions featuring a unique ring-shaped configuration of its active components

9-phase configuration, SMART and other PRINEM technology options

are available.

are available.

Exceptional Reliability

Controller

Lower Cost Compared to Synchronous Motors

12

simple and reliable

12

1. Active zone is on the outer radius leaving the

internal space free for blades, spokes, or hollow

internal space free for blades, spokes, or hollow

2. Both external and internal rotation versions

3. Available in both asynchronous and synchronous versions based on proven industrial technologies

Key Heatures

Ventilation and pumping systems, transport, conveyors

and industrial drive wheels. It serves as a direct alternative

in any application currently using synchronous ring motors.

and industrial drive wheels. It serves as a direct alternative

in any application currently using synchronous ring motors.

It has significant potential to replace synchronous

motors due to its simplified design and lower cost

motors due to its simplified design and lower cost

Applications

С технологиями PRINEM моторы вроде Xiaomi Super Motor V8s (425 кВт, 30 000 об/мин) можно модернизировать до 2+ МВт

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

с ростом оборотов, но гораздо ценнее и перспективнее использовать возможность перенести эффективные рабочие обороты в «меньшую сторону»

PRINEM PowerRing

Innovative induction motor design for industrial

solutions featuring a unique ring-shaped configuration

of its active components

solutions featuring a unique ring-shaped configuration

of its active components

9-phase configuration, SMART and other PRINEM

technology options are available

technology options are available

1

Lower Cost Compared to Synchronous Motors

Ideal for Integration Into Existing Systems

Exceptional Reliability

Controller

simple and reliable

2

Key Features

1. Active zone is on the outer radius leaving

the internal space free for blades, spokes, or hollow

the internal space free for blades, spokes, or hollow

2. Both external and internal rotation versions

3. Available in both asynchronous and synchronous versions based on proven industrial technologies

3

Key Features

Ventilation and pumping systems, transport,

conveyors and industrial drive wheels. It serves as a direct alternative in any application currently using synchronous ring motors.

conveyors and industrial drive wheels. It serves as a direct alternative in any application currently using synchronous ring motors.

It has significant potential to replace synchronous

motors due to its simplified design and lower cost

motors due to its simplified design and lower cost

Applications